60 Tuj Nplej Hmoov Zeb Tsob Ntoo

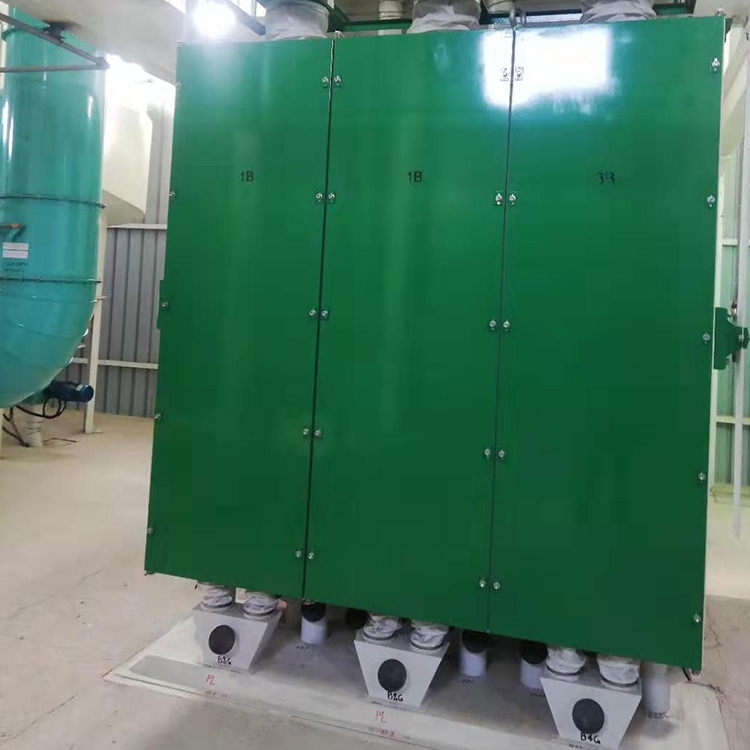

Nplej hmoov zeb cog yog tsim thiab ntsia ua ke nrog kev txhawb nqa steel qauv.Cov qauv kev txhawb nqa tseem ceeb yog ua los ntawm peb theem: cov mills rau cov menyuam yog nyob rau hauv pem teb, cov sifters tau nruab rau hauv pem teb, cov cyclones thiab cov kav dej pneumatic yog nyob rau hauv pem teb thib ob.

Rhiav qhov siab yog qhov qis los txo cov neeg siv khoom peev.Kev xaiv PLC tswj tshuab tuaj yeem paubcentral tswj nrog qib siab ntawm automationthiab ua haujlwm yooj yim dua thiab hloov tau yooj yim dua.Lub qhov cua nyob ze tuaj yeem zam cov plua plav txeej kom khaws ciakev ua haujlwm huv huv siab.Tag nrho cov zeb tuaj yeem muab tso rau hauv ib lub tsev khaws khoom thiab cov qauv tsim tuaj yeem ua taucustomized raws li kev xav tau sib txawv.

| Qauv | CTWM-60 |

| Peev xwm (t / 24h) | 60 TSI |

| Roller Mill Qauv | Phau ntawv |

| Sifter Qauv | ntxaib sifter |

| Daim Ntawv Ncua Nroj Tsuag | 3-sifting, 2-scouring, 2-destoneing, 1-ntxuav |

| Mill Flow Daim Ntawv | 4-tawg, 5-txo, 1T |

| Tag nrho lub zog (kw) | 220 |

| Qhov chaw (LxWxH) | 35 x 8 x 11 m |

Kev tu huv

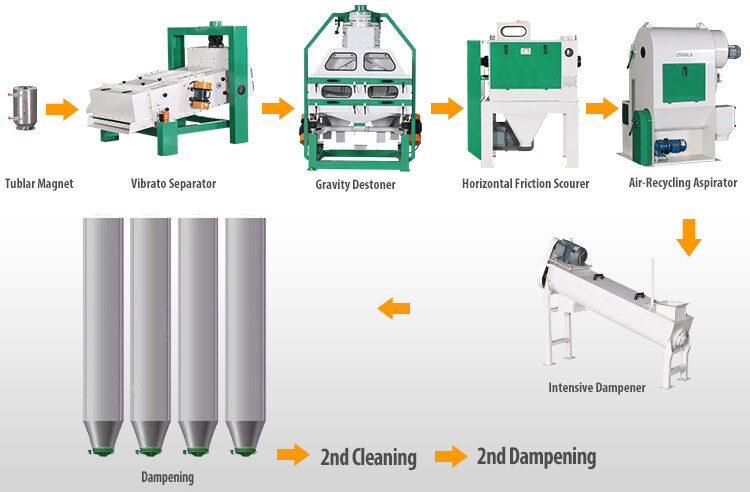

Hauv seem tu, peb txais kev ziab-hom tu tshuab.Nws feem ntau suav nrog 2 zaug sifting, 2 zaug scouring, 2 zaug de-stoneing, ib zaug purifying, 4 zaug aspiration, 1 mus rau 2 zaug dampening, 3 zaug sib nqus sib nqus, thiab lwm yam.Hauv seem tu, muaj ntau lub tshuab aspiration uas tuaj yeem txo cov plua plav tawm ntawm lub tshuab thiab ua kom muaj chaw ua haujlwm zoo.Qhov no yog ib daim ntawv nyuaj tag nrho ntws uastuaj yeem tshem tawm feem ntau ntawm cov coarse offal, nruab nrab loj offal, thiab nplua offal hauv cov nplej.

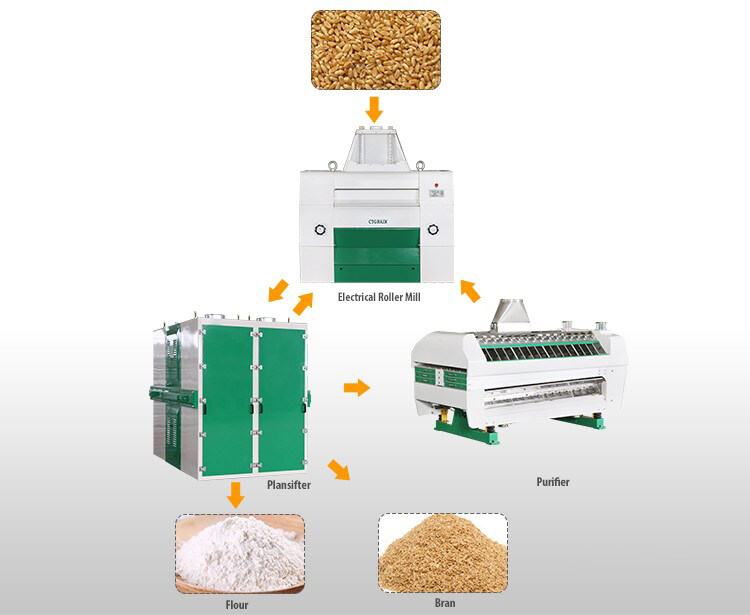

Milling Tshooj

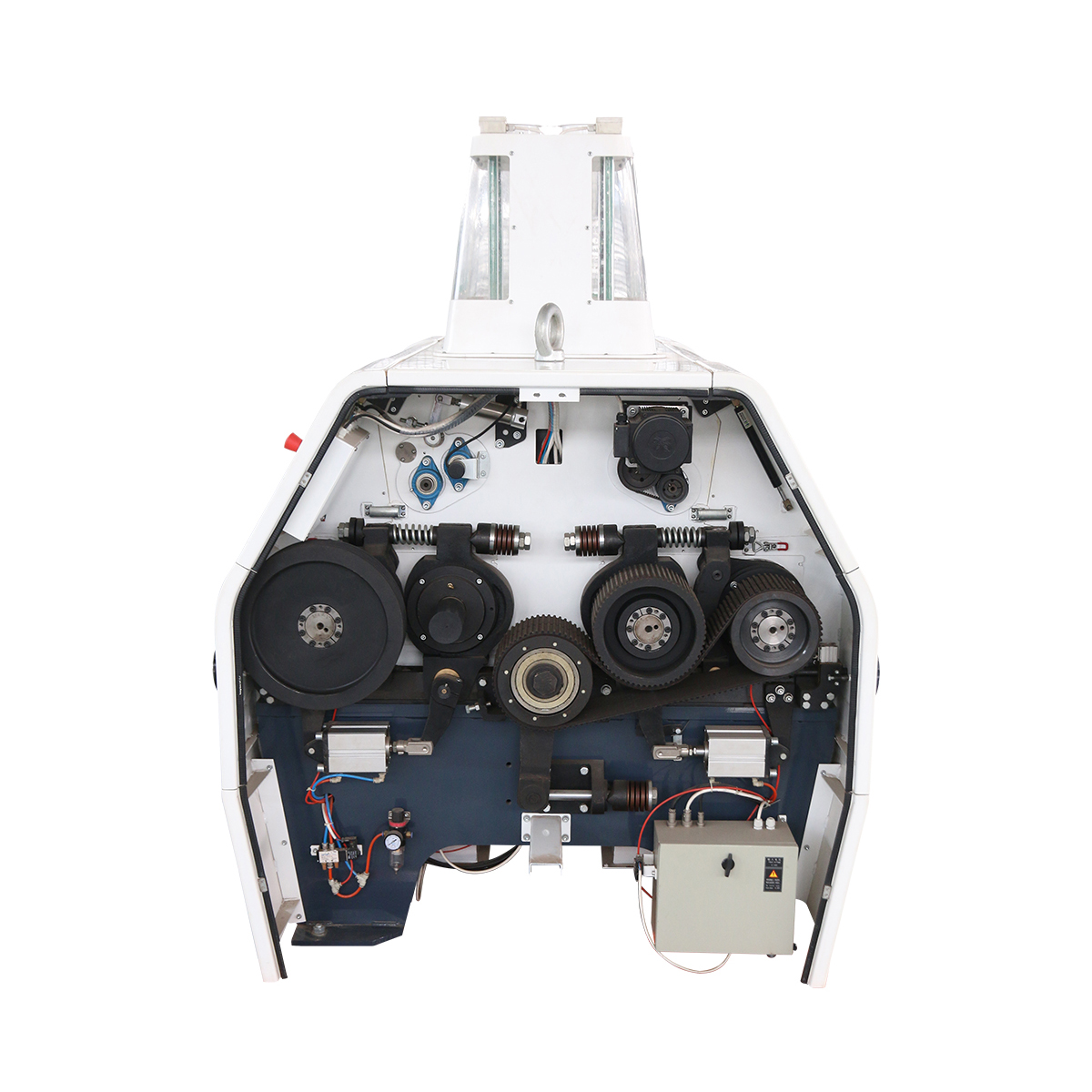

Hauv seem milling,muaj plaub hom tshuab rau zeb nplej rau hmoov.Lawv yog 4-Tso system, 7-Txo qhov system, 1-Semolina system, thiab 1-Tail system.Tag nrho cov qauv tsim yuav lav tias tsawg dua bran yog tov rau hauv bran thiabtus hmoov nplej yog maximized.Vim hais tias ntawm qhov zoo-tsim pneumatic lifting system, tag nrho cov khoom zeb yog pauv los ntawm lub siab-siab kiv cua.Lub milling chav yuav huv si thiab huv si rau aspiration saws.

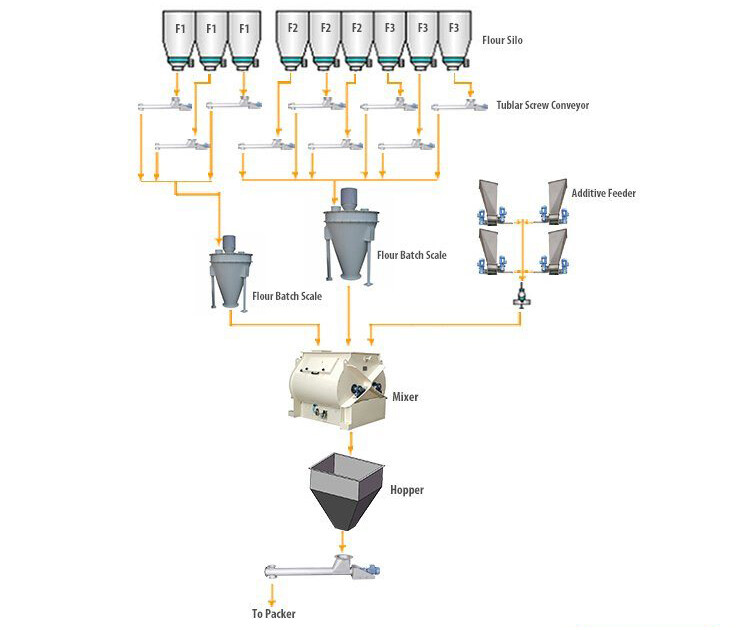

Flour Blending Section

Cov hmoov nplej hmoov nplej feem ntau muaj pneumatic conveying system, bulk hmoov cia system, blending system, thiab cov hmoov nplej zaum kawg.Nws yog txoj hauv kev zoo tshaj plaws thiab muaj txiaj ntsig zoo los tsim cov hmoov nplej zoo thiab ua kom ruaj khov ntawm cov hmoov nplej zoo.Rau qhov no 200TPD hmoov zeb packing thiab blending system, muaj 3 hmoov cia bins.Cov hmoov nplej hauv cov thawv ntim khoom yog tshuab rau hauv 3 lub hnab ntim cov hmoov nplej thiab ntim thaum kawg.

Ntim Ntu

Lub tshuab ntim khoom muaj cov yam ntxwv ntawm kev ntsuas qhov tseeb, kev ntim khoom ceev ceev, txhim khu kev qha thiab ua haujlwm ruaj khov.Nws ua tauhnyav thiab suav tau, thiab nws tuaj yeem khaws qhov hnyav.Lub tshuab packing muaj covkev ua txhaum ntawm tus kheej kev kuaj mob.Lub tshuab ntim khoom yog nrog lub hnab ntim ntim-clamping mechanism, uas tuaj yeem tiv thaiv cov khoom los ntawm kev xau tawm.Cov khoom ntim tshwj xeeb suav nrog 1-5kg, 2.5-10kg, 20-25kg, 30-50kg.Cov neeg tuaj yeem xaiv cov ntim sib txawv raws li qhov yuav tsum tau ua .

Hluav taws xob tswj thiab tswj

Peb yuav muab cov khoom siv hluav taws xob tswj hluav taws xob, cov teeb liab cable, cable tais thiab cable ladders, thiab lwm yam khoom siv hluav taws xob.Lub substation thiab lub cev muaj zog cable tsis suav nrog tsuas yog cov neeg siv khoom tshwj xeeb xav tau.PLC tswj qhov system yog qhov kev xaiv xaiv rau cov neeg siv khoom.Hauv PLC tswj qhov system, tag nrho cov tshuab yog tswj los ntawm Programmed Logical Controller uas tuaj yeem ua kom lub tshuab ua haujlwm ruaj khov thiab ua tau zoo.Lub kaw lus yuav ua qee qhov kev txiav txim siab thiab ua qhov cuam tshuam raws li thaum twg lub tshuab ua txhaum lossis nres qhov txawv txav.Nyob rau tib lub sijhawm, nws yuav ceeb toom thiab ceeb toom tus neeg teb xov tooj kom daws qhov txhaum.

Ua tiav cov nplej hmoov nplej ua cov nroj tsuag txais ntau hom kev teeb tsa rau kev xaiv sib txawv.Lawv yog cov sib dhos kab tsim, tsim nyog layout, zoo nkauj kev ua tau zoo.Cov hmoov ua cog yog nrog advanced technical txheej txheem thiab hloov tau yooj yim.Nws tuaj yeem tsim cov hmoov nplej thiab cov hmoov nplej tshwj xeeb, thiab lwm yam.Rollers mills yog tsim los ntawm cov khoom siv thiab tswj los ntawm phau ntawv lossis pneumatic hom.Nws tuaj yeem ua rau cov nyhuv sib tsoo zoo dua piv nrog lwm cov hmoov nplej zoo tib yam.

Txog Peb

Txog tam sim no peb tau muab peb cov khoom thiab kev pabcuam rau cov neeg siv khoom los ntawm ntau dua 60 lub tebchaws, suav nrog Australia, Lub Tebchaws Yelemees, Britain, Argentina, Peru, Thaib, Tanzania, South Africa, thiab lwm yam.lwm.

FAQ

1. Q: Lub tshuab ua hmoov nplej puas tuaj yeem ua pob kws?

A: Tsis yog, nws yog vim cov pobkws thiab hom qoob mog Lub cev muaj zog sib txawv, zoo li cov duab, thiab cov tawv tawv, txhua qhov sib txawv, thiab cov khoom kawg hmoov loj kuj txawv.Koj tuaj yeem yuav peb cov pob kws hmoov nplej cog.

2. Q: Cov nplej hmoov nplej puas tuaj yeem ntim cov hnab sib txawv?

A: Yog, lub tshuab ntim khoom tuaj yeem ntim 1kg-5kg; 5kg-20kg, 20-50kg hnab.

3. Q: Lub tshuab nplej nplej puas tuaj yeem ua haujlwm nrog Generator?

A: Yog lawm, cov hmoov nplej zeb kab tuaj yeem khiav nrog Generator.

4. Q: Koj puas yog cov chaw tsim khoom?

A: Yog, Peb yog cov kws tshaj lij hmoov milling tshuab chaw tsim khoom.

5. Q: Koj puas tuaj yeem pab txhim kho lub tshuab?

A: Yog, peb cov engineers tuaj yeem qhia txog kev teeb tsa, kev sim khiav, thiab kev cob qhia cov neeg ua haujlwm hauv zos.Engineers muaj rau kev pabcuam machinery txawv teb chaws tom qab-muag Service

6. Q: Lub sijhawm lav yog dab tsi?

A: Peb lub sijhawm lav yog 12 lub hlis, yog li koj tuaj yeem ntseeg peb thiab peb lub tshuab zoo.

Vim li cas thiaj xaiv peb

Peb lub tuam txhab yog cov chaw tsim khoom lag luam ntawm cov nplej nplej zeb cog thiab pob kws zeb nroj tsuag nrog ntau tshaj 24 xyoo ntawm kev paub.Lub Hoobkas tsim ntawm 15000 square meters.Peb cov pob kws zeb cog thiab nplej hmoov zeb cog tau dhau ISO SGS CE daim ntawv pov thawj.