200 Tuj Nplej Hmoov Zeb Tsob Ntoo

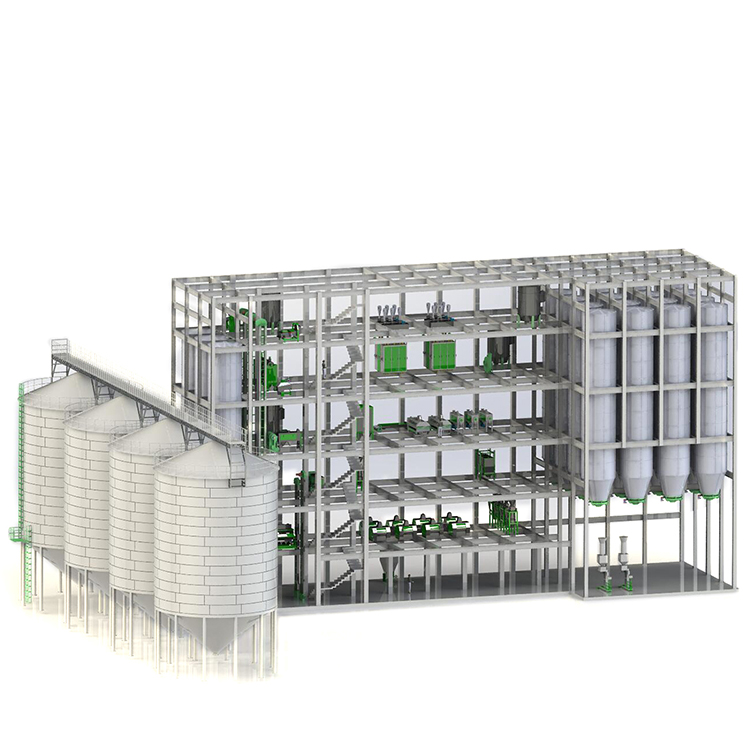

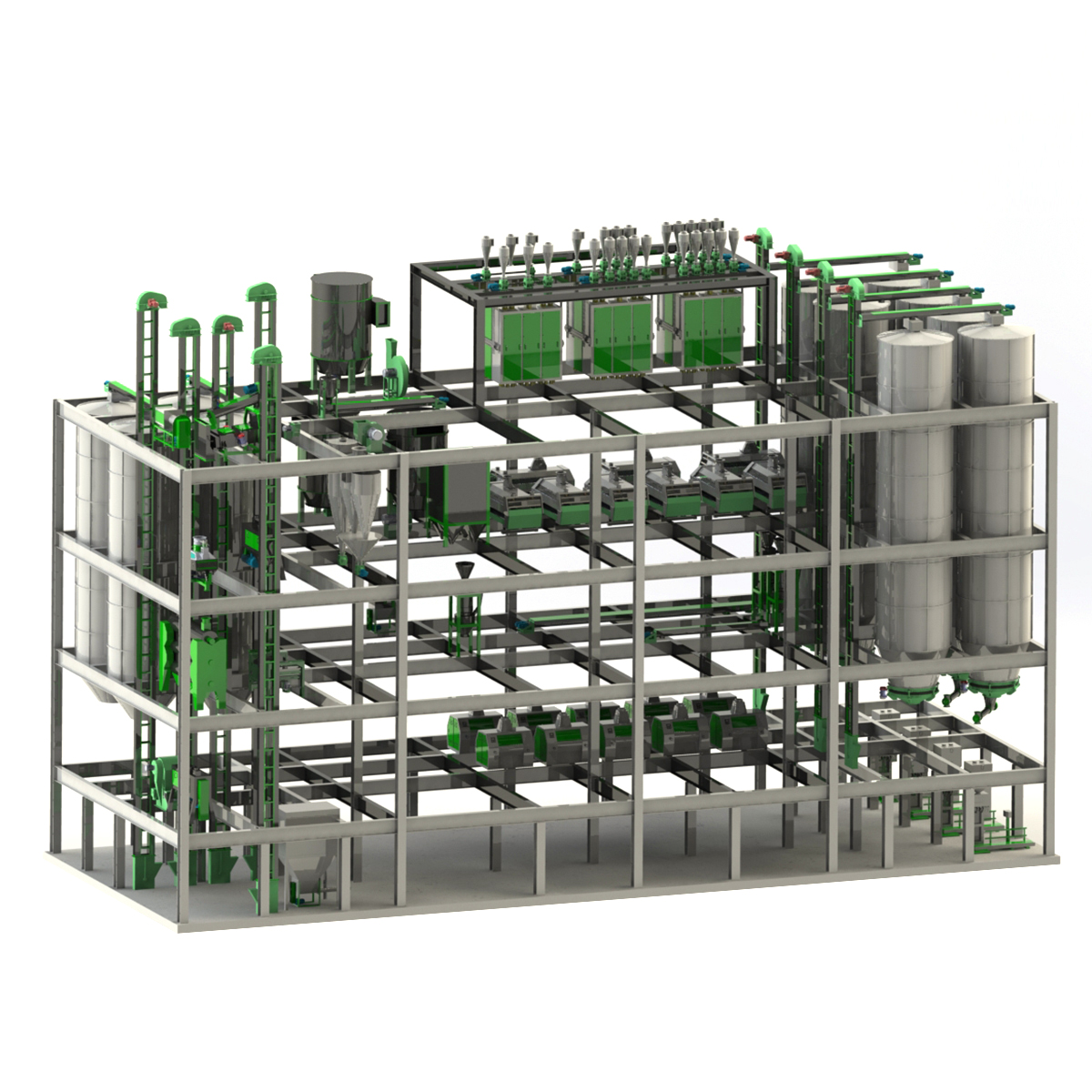

Cov tshuab no feem ntau yog ntsia rau hauv cov tsev ua vaj tse los yog cov khoom siv hlau, uas feem ntau yog 5 mus rau 6 zaj dab neeg siab (xws li cov nplej silo, hmoov cia tsev, thiab hmoov nplej sib xyaw).

Peb cov hmoov milling kev daws teeb meem yog tsim los raws li Asmeskas cov nplej thiab Australian dawb hom nplej.Thaum milling ib hom nplej,hmoov extraction tus nqi yog 76-79%, thaum cov hmoov tshauv yog 0.54-0.62%.Yog tias muaj ob hom hmoov nplej, cov hmoov nplej rho tawm thiab cov hmoov tshauv yuav yog 45-50% thiab 0.42-0.54% rau F1 thiab 25-28% thiab 0.62-0.65% rau F2.

| Qauv | CTWM-200 |

| Muaj peev xwm | 200 TSI |

| Roller Mill Qauv | Pneumatic / Hluav taws xob |

| Installation zog (kw) | 450-500 (tsis suav) |

| Worker Per Shift | 6-8 |

| Kev siv dej (t / 24h) | 10 |

| Qhov chaw (LxWxH) | 48 x 12 x 28 m |

Kev tu huv

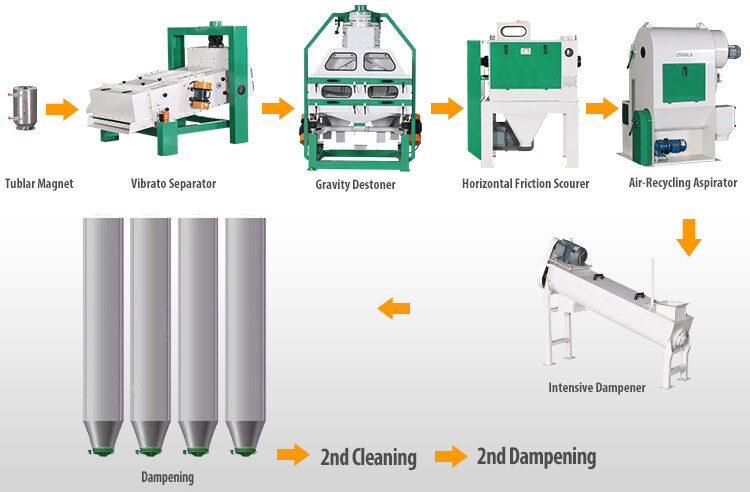

Hauv seem tu, peb txais kev ziab-hom tu tshuab.Nws feem ntau suav nrog 2 zaug sifting, 2 zaug scouring, 2 zaug de-stoneing, ib zaug purifying, 4 zaug aspiration, 1 mus rau 2 zaug dampening, 3 zaug sib nqus sib nqus, thiab lwm yam.Hauv seem tu, muaj ntau lub tshuab aspiration uas tuaj yeem txo cov plua plav tawm ntawm lub tshuab thiab ua kom muaj chaw ua haujlwm zoo.Qhov no yog ib daim ntawv nyuaj tag nrho ntws uastuaj yeem tshem tawm feem ntau ntawm cov coarse offal, nruab nrab loj offal, thiab nplua offal hauv cov nplej.

Milling Tshooj

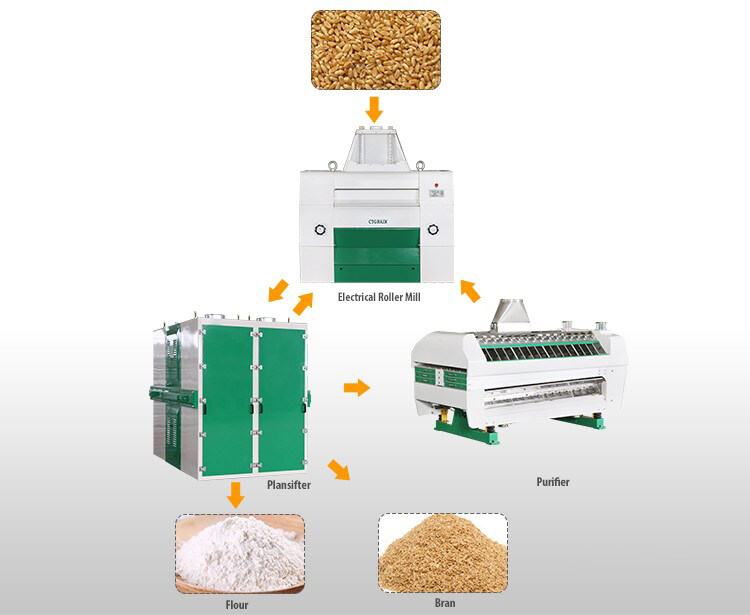

Hauv seem milling,muaj plaub hom tshuab rau zeb nplej rau hmoov.Lawv yog 4-Tso system, 7-Txo qhov system, 1-Semolina system, thiab 1-Tail system.Tag nrho cov qauv tsim yuav lav tias tsawg dua bran yog tov rau hauv bran thiabcov hmoov nplej yog maximized.Vim hais tias ntawm qhov zoo-tsim pneumatic lifting system, tag nrho cov khoom zeb yog pauv los ntawm lub siab-siab kiv cua.Lub milling chav yuav huv si thiab huv si rau aspiration saws.

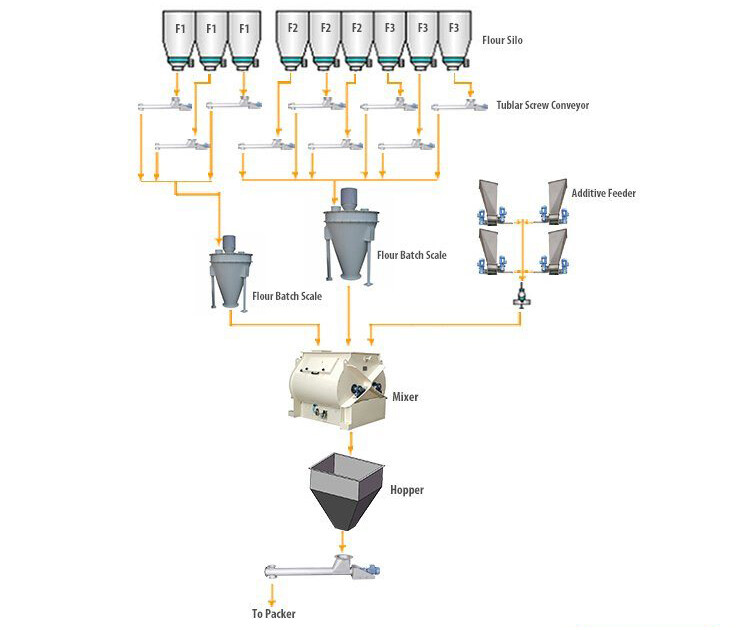

Flour Blending Section

Cov hmoov nplej hmoov nplej feem ntau muaj pneumatic conveying system, bulk hmoov cia system, blending system, thiab cov hmoov nplej zaum kawg.Nws yog txoj hauv kev zoo tshaj plaws thiab muaj txiaj ntsig zoo los tsim cov hmoov nplej zoo thiab ua kom ruaj khov ntawm cov hmoov nplej zoo.Rau qhov no 200TPD hmoov zeb packing thiab blending system, muaj 3 hmoov cia bins.Cov hmoov nplej hauv cov thawv ntim khoom yog tshuab rau hauv 3 lub hnab ntim cov hmoov nplej thiab ntim thaum kawg.

Ntim Ntu

Lub tshuab ntim khoom muaj cov yam ntxwv ntawm kev ntsuas qhov tseeb, kev ntim khoom ceev ceev, txhim khu kev qha thiab ua haujlwm ruaj khov.Nws ua tauhnyav thiab suav tau, thiab nws tuaj yeem khaws qhov hnyav.Lub tshuab packing muajkev ua txhaum ntawm tus kheej kuaj mob.Lub tshuab ntim khoom yog nrog lub hnab ntim ntim-clamping mechanism, uas tuaj yeem tiv thaiv cov khoom los ntawm kev xau tawm.Cov khoom ntim tshwj xeeb suav nrog 1-5kg, 2.5-10kg, 20-25kg, 30-50kg.Cov neeg tuaj yeem xaiv cov ntim sib txawv raws li qhov yuav tsum tau ua .

Hluav taws xob tswj thiab tswj

Peb yuav muab cov khoom siv hluav taws xob tswj hluav taws xob, cov teeb liab cable, cable tais thiab cable ladders, thiab lwm yam khoom siv hluav taws xob.Lub substation thiab lub cev muaj zog cable tsis suav nrog tsuas yog cov neeg siv khoom tshwj xeeb xav tau.PLC tswj qhov system yog qhov kev xaiv xaiv rau cov neeg siv khoom.Hauv PLC tswj qhov system, tag nrho cov tshuab yog tswj los ntawm Programmed Logical Controller uas tuaj yeem ua kom lub tshuab ua haujlwm ruaj khov thiab ua tau zoo.Lub kaw lus yuav ua qee qhov kev txiav txim siab thiab ua qhov cuam tshuam raws li thaum twg lub tshuab ua txhaum lossis nres qhov txawv txav.Nyob rau tib lub sijhawm, nws yuav ceeb toom thiab ceeb toom tus neeg teb xov tooj kom daws qhov txhaum.

| Technical Specification: | |

| Yam khoom | Kev piav qhia |

| a | Peev xwm: 200t / 24h |

| b | Roller zeb qauv: Pneumatic / hluav taws xob |

| c | Luas x Dav x Qhov siab = 48 x 12 x 28 m |

| d | Kev teeb tsa lub zog: 484Kw.Lub zog siv rau kev tsim ib tuj hmoov tsis ntau tshaj 65kWh ntawm ib txwm muaj. |

| e | Kev siv dej: 0.6T / H |

| f | Tus neeg ua haujlwm xav tau: 4-6 tus neeg |

| g | Cov hmoov nplej rho tawm yog 76-79%, thaum cov hmoov tshauv yog 0.54-0.62%.Yog tias muaj ob hom hmoov nplej, cov hmoov nplej rho tawm thiab cov hmoov tshauv yuav yog 45-50% thiab 0.42-0.54% rau F1 thiab 25-28% thiab 0.65-0.70% rau F2.Cov ntsiab lus tshauv saum toj no yog nyob rau hauv ntub dej. Cov ntaub ntawv no yog nyob ntawm cov nplej zoo uas zoo ib yam lossis zoo dua qib 2 durum nplej (los ntawm Asmeskas lossis Australia.) |

Nco tseg:

1, Cov ncauj lus kom ntxaws tu thiab milling ntws cov nplooj ntawv tuaj yeem tsim raws li cov neeg siv khoom tshwj xeeb thiab cov chaw cog qoob loo.

2, 30% tso nyiaj los ntawm TT, thiab 70% them ua ntej xa khoom xa tuaj.

3, Lub sij hawm xa tuaj: tsis pub dhau 90 hnub tom qab tau txais cov nyiaj them poob haujlwm thiab tag nrho cov ntsiab lus ntawm spec.paub tseeb.

Qhov no 200t nplej hmoov milling cog hloov cov qauv tsim ntawm cov txheej txheem thev naus laus zis.Nws nta txoj kev ntev ntawm kev ua hmoov nplej, uas siv cov txheej txheem tawg, khawb qhov system, txo qhov system, thiab ua rau cov hmoov nplej sib npaug thiab tag nrho.Cov txheej txheem thev naus laus zis tshiab muaj 17 chav kawm ntawm cov txheej txheem thev naus laus zis ntawm kev sib tsoo, uas tsis tsuas yog ua kom cov hmoov nplej zoo thiab cov xim dawb ntawm cov hmoov nplej.Cov ntsiab lus tshauv yog tsawg, kuj txhim kho cov hmoov nplej extraction thiab txo lub zog noj.

Txog Peb