Nplej pob kws Grain Conveying Belt Conveyor

Qhov ntev ntawm peb txoj siv conveyor yog li ntawm 10m txog 250m.Cov siv ceev ceev yog 0.8-4.5m / s.Raws li lub tshuab ua tshuab thoob ntiaj teb, lub tshuab conveying no tau siv dav hauv kev lag luam nplej, fais fab nroj tsuag, chaw nres nkoj thiab lwm lub sijhawm rau kev xa cov granule, hmoov, lumpish lossis bagged cov ntaub ntawv, xws li nplej, thee, mine, thiab lwm yam.

Lub ntsiab qauv thiab lub hauv paus ntsiab lus ua haujlwm

Rotor rollers txhawb nqa lub nplhaib siv khiav thiab hloov ntau yam khoom ntawm nws mus ntev.

Feature

1. Ob qho khoom siv thiab txoj siv sia ua haujlwm ruaj khov.Tsis muaj kev sib txawv ntawm txoj siv tawv lossis cov khoom xau tshwm sim.

2. Txoj siv conveyor tuaj yeem tuaj yeem kho hom lossis hom txawb, thiab tuaj yeem txuas kab rov tav lossis nrog lub kaum sab xis.

3. Cov khoom siv yog tsav los ntawm motorized rollers lossis gear motors.

4. Qhov no conveyor system los nrog cov qauv yooj yim, tsis tshua muaj suab nrov, thiab yooj yim los tswj.

5. Kev xaiv dov ntau yam ntawm txoj siv tshaj tawm (0.8m / s ~ 4.5m / s), Kev kub ceev thiab muaj peev xwm ntawm txoj siv tawv ua rau kev ua haujlwm siab ntawm peb txoj siv conveyor.

6. Rau txhua yam granular, hmoov, lumpish cov ntaub ntawv, thiab cov khoom ntim.

Technical Parameters List

| Hom | Muaj peev xwm | Linear Ceev | Dav | Hwj chim |

| TPDS 50 | 80-100 | 1-3 | 500 | Nyob ntawm |

| TIAB SA 65 | 165-200 : kuv | 1-3 | 650 | |

| TIAB SA 80 | 240-300 Nws | 1-3 | 800 | |

| TSO 100 | 400-500 | 1-3 | 1000 | |

| TIAB SA 120 | 580-700 Nws | 1-3 | 1200 | |

| TIAB SA 140 | 750-900 Nws | 1-3 | 1400 |

Khoom Paub meej

Rubber Conveyor siv:

siv cov paj rwb canvas lossis tshuaj fiber ntau daim ntaub canvas los ua cov txheej txheem tseem ceeb, nrog cov txheej txheem zoo hnav-resistant yas;hom roj hmab conveyor siv no yog elastic thiab saj zawg zog.

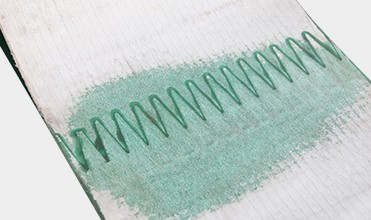

Siv lub fork welding:

Qhov zoo ntawm kev sib koom ua ke ncaj qha cuam tshuam rau tag nrho lub zog ntawm txoj siv conveyor.Cov diav rawg sib koom vuam muaj lub zog siab, tuaj yeem tiv thaiv cov tub ntxhais corrosion kom muaj lub neej ua haujlwm ntev.Kev sib koom ua ke yog du thiab tsis muaj lub caij nyoog, txoj siv conveyor ua haujlwm zoo nrog tsis muaj kev cuam tshuam, thiab muaj kev hloov pauv tau zoo thiab muaj peev xwm trough.

Drum-shaped roller:

nrog nruab nrab tsa cov menyuam tuaj yeem tiv thaiv txoj siv conveyor kev sib txawv.

Tensioning ntaus ntawv:

Txhawm rau kom muaj kev nruj txaus, kom tsis txhob siv txoj siv conveyor skidding ntawm tus tsav cov menyuam thiab ntau sagging.

Idler roller:

kev txhawb nqa khoom siv rau conveying siv, tsis muaj kev saib xyuas, me me dhia, du kev sib hloov, kev pab lub neej ntev.Ntau hom kev coj tus kheej lub rooj zaum thiab cov qauv sib khi rau cov neeg siv xaiv, ntau txoj kev Labyrinth foob tuaj yeem tiv thaiv cov plua plav thiab dej nkag.High-density steel yeeb nkab yog siv los xyuas kom meej cov menyuam tsis muaj kev vibration thiab suab nrov.

Txog Peb

Peb Cov Kev Pabcuam

Peb cov kev pabcuam los ntawm kev xav tau kev pab tswv yim, kev tsim qauv, kev tsim khoom, kev teeb tsa hauv tsev, kev cob qhia cov neeg ua haujlwm, kho thiab tu, thiab kev lag luam txuas ntxiv.

Peb pheej tsim thiab hloov kho peb cov thev naus laus zis kom tau raws li txhua tus neeg siv khoom xav tau.Yog tias koj muaj lus nug lossis teeb meem hais txog cov hmoov nplej milling teb, los yog koj tab tom npaj tsim cov hmoov nplej zeb cog, thov koj xav tiv tauj peb.Peb cia siab tias yuav hnov los ntawm koj.

Peb Lub Hom Phiaj

Muab cov khoom lag luam zoo thiab cov kev daws teeb meem kom ua kom cov neeg siv khoom tau txais txiaj ntsig ntau.

Peb Qhov Tseem Ceeb

Customer First, Integrity Oriented, Nruam Innovation, Siv zog rau Perfection.

Peb Culture

Qhib thiab sib qhia, yeej-yeej kev koom tes, ua siab ntev thiab loj hlob.